Choosing the Right Way Covers for Your CNC Machines: A Comprehensive Buyer's Guide

When it comes to CNC machines, ensuring their longevity and efficiency is crucial for any manufacturing operation. One often overlooked aspect is the choice of way covers, which play a vital role in protecting machine components from dust, debris, and other contaminants. Choosing the right way covers for your CNC machines can significantly impact their performance and maintenance costs.

Understanding the Types of Way Covers

Way covers come in various types, each designed for specific applications and machine configurations. The most common types include telescopic steel covers, bellows, and roll-up covers. Each has its own advantages, and selecting the appropriate one depends on factors such as machine environment, speed, and space constraints.

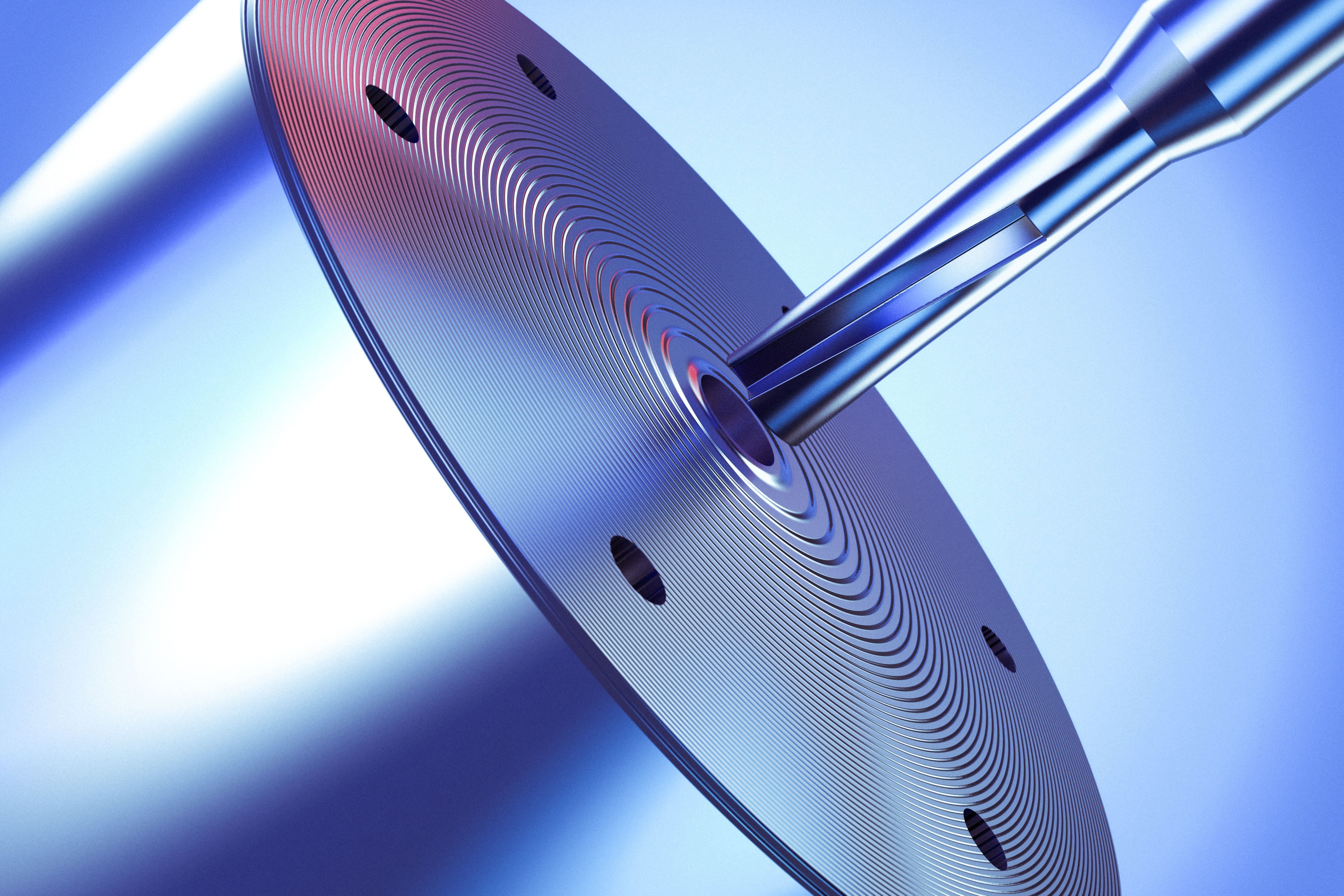

Telescopic Steel Covers

Telescopic steel covers are known for their durability and are ideal for environments with heavy debris or high-speed operations. They provide excellent protection against sharp chips and coolant, making them suitable for heavy-duty CNC machines. However, they can be more expensive and require precise installation.

Bellow Covers

Bellow covers, on the other hand, offer flexibility and are often used in environments where space is limited. They can be customized to fit various shapes and sizes, providing effective protection while allowing for smooth movement. These covers are typically less expensive than steel covers but may not offer the same level of protection against sharp particles.

Key Considerations When Choosing Way Covers

When selecting the right way covers, it's essential to consider certain factors to ensure optimal performance. The first step is to assess the operational environment of your CNC machine. If your machine operates in a high-debris environment, more robust covers like telescopic steel might be necessary.

Speed and Movement

The speed and movement of your CNC machine also play a crucial role in determining the type of way cover needed. High-speed machines may benefit from roll-up covers that offer minimal resistance and can retract quickly, ensuring smooth operation without hindrance.

Maintenance and Cost

Another critical factor is maintenance and cost. While durable covers may have a higher initial cost, they often result in lower long-term maintenance expenses. Evaluate the total cost of ownership, including installation and potential downtime due to maintenance.

Installation and Customization Options

Proper installation is a key factor in maximizing the effectiveness of way covers. Some covers may require professional installation to ensure they function correctly and do not interfere with machine operations. Additionally, many suppliers offer customization options to fit specific machine requirements, which can enhance performance and protection.

In conclusion, selecting the right way covers for your CNC machines is an investment in protecting your equipment and ensuring efficient operations. By understanding the different types available, considering environmental factors, speed, maintenance costs, and installation needs, you can make an informed decision that will benefit your manufacturing process in the long run.